Okay guys, it's time for a little tech talk

We have received quite a few inquiries lately regarding intercoolers and what to look for when purchasing an intercooler upgrade. Rather than reiterate the same information, we though that it would be a good idea to compose a brief writeup going over the basics of what makes up an intercooler.

There are two types of intercooler cores; bar-and-plate and tube-and-fin.

Tube-and-Fin

Due to the nature of design tube-and-fin intercooler cores typically weigh less than a bar-and-plate design. A 3.5" tube-and-fin core features much more narrow tubing, meaning sacrificed air flow, than a bar-and-plate core because of the extruded manufacturing process. Another weakness of this design is the fact that it is more susceptible to leaking.

Bar-and-Plate

Though usually a bit heavier, bar-and-plate intercooler cores work extremely well as a heatsink, soaking up heat and keeping the charge relatively cool. The core then dissipates the heat once the vehicle is in motion, whereas a tube-and-fin core struggles. Bar-and-plate cores also are less susceptible to leaking, meaning that they can take the abuse from road debris and high boost for many years to come. Bar-and-plate cores pack a much more dense fin pitch, which means better cooling and more internal air flow.

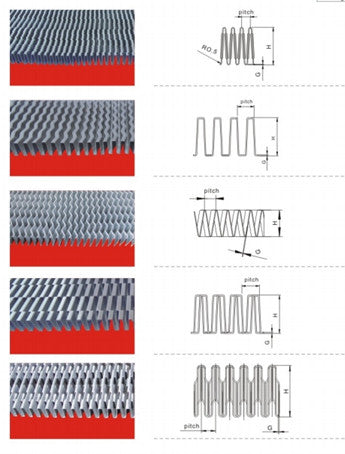

Fin Pitch and Design

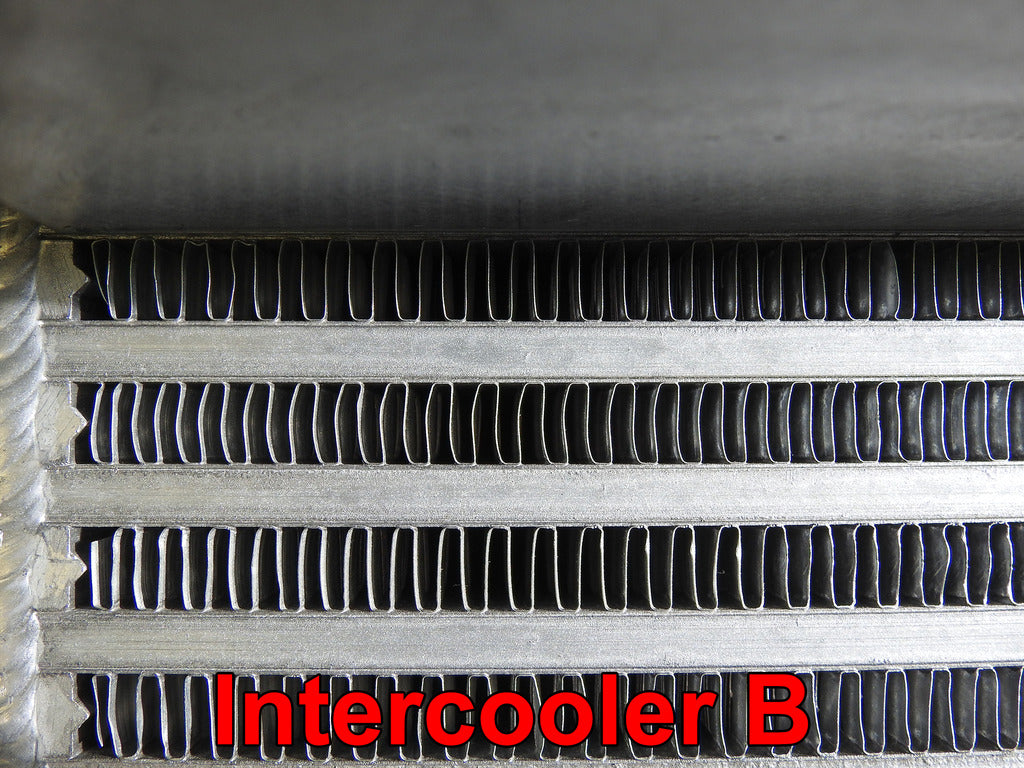

Above we have two different, yet similar bar-and-plate intercooler cores; Intercooler A and Intercooler B. Intercooler A happens to be our prototype 1.5T 10th Gen Civic intercooler core (production intercoolers have two tweaks that we felt would allow better cooling and more charge air flow). Intercooler B is a generic Chinese intercooler. Looking at the two the difference in FPI, or fins per inch, becomes very apparent. As stated earlier, one of the intercooler's main purposes is to absorb and dissipate the heat as much as possible. In short, higher FPI means more cooling surface which equates to better cooling. Intercooler A will do a much better job in terms of cooling than intercooler B.

Above are side angles of the same intercooler cores listed earlier. There are numerous different types of fin designs for different reasons, but the most common in this application are the serrated, louvered fins and offset fins. Though it is simply our preference, we have found serrated/louvered fins to work extremely in terms of cooling the external fins. Louvers help to add more surface cooling area. Notice how much more material is visible to the eye with Intercooler core A in comparison to Intercooler core B? The most common type of fin design for internal fins are offet fins, because they still allow adequate cooling without the added obstruction of a louvered fin. This means less pressure drop.

There is a happy medium for FPI in terms of air flow and cooling. Higher fin density typically means the higher the pressure drop due to charge air flow restriction. This is where mathematics comes in. We will need to calculate compressor lbs/min or CFM, charge air temps, engine displacement and a few other factors to make sure an intercooler core can move as much charge air as possible while keeping the air cool. Too large of a core can harm turbo spool and response, while too small of a core can become a choke point and lose cooling efficiency.

Conclusion

Having a variety of options on the market are great for everybody. They keep manufacturers on their toes and keep pushing us to make the best products possible. Variety also keeps pricing competitive and a wide selection for you, the consumer. With that being said, please be sure to do your homework when choosing an intercooler, or any product at that. There will be many attempts to enter this market and introduce inferior intercoolers due to the universality of the Si and Non-Si models from companies looking to make a quick sale from unsuspecting buyers. Not all aftermarket intercoolers are "upgrades," and not all intercoolers are the same. Good things come to those who wait!