We've been hard at work over the past few weeks designing and running numbers for our new 1.5T front mount intercooler kit. A lot of time and thought was put into developing what we feel will be the most-efficient, best-fitting intercooler kit on the market.

One of the key selling points of the 1.5T, Civic X platform is its lightweight, highly efficient engine and chassis. So efficient, in fact, that Honda engineers have continuously prided themselves for how well the factory intercooler flows and cools for such a lightweight unit. Because of this, our intercooler core of choice for this application is a dense 24"x6.3"x3.5" 500hp bar-and-plate core. We have used this core in our BRZ/FR-S/FT86 turbo kit with great success, proving itself still efficient at well over 500hp. The size of this intercooler also allows it to be a rather lightweight assembly (about 10lbs heavier than stock for the whole kit), meaning we are able to offer a similarly low-weight intercooler that performs much better than stock.

Our goal was to offer an intercooler setup that didn't notably affect or create turbo lag, but still offers headroom for guys looking to make big power in the future. In the past we have been a fan of our larger 600hp cores (that have been proven to over 900whp) for big(ger) turbo and larger displacement applications, but it is important to keep in mind that these cars are only a 1.5L with a very small turbocharger. After running some numbers we felt that this 500hp core would be the most ideal size for customers with stock turbos, future stock-replacement turbo upgrades and a possible future PRL Motorsports turbo kit!

This intercooler will utilize factory mounting spots with our embossed end tanks as well as all factory air ducts/shrouds. Kits will come standard with upgraded hot and cold side intercooler piping that utilize smooth radii and hose/tubing diameters designed with small and larger turbochargers in mind. Like most of our PRL product line, no cutting, fitting or trimming will be required. Kits will come with all hardware needed for a seemless install. Stay tuned for more pictures and info as we finish our design and begin testing!

Our prototype cast end tanks and interooler core has been mocked up and fitted to finalize intercooler piping and silicone. Testing is right around the corner! Once this is done we should have a realistic ETA.

More updates! Our prototype is complete! We will be testing next week! All piping will come standard powdercoated textured black.

FMIC Friday? Finally we have some dyno testing and data for you guys!

Here is an overall comparison from what we have gathered thus far with our 2017 Civic Si in terms of gains. We chose the dyno runs to compare because these are all 4th gear pulls with identical coolant temps and knock values (~55%). All of these pulls are untuned and using the factory Honda ECU mapping.

- 100% Stock Civic Si Baseline: 186 hp & 215 ft/lbs tq

- 100% Stock Civic Si + Stage 1 Intake: 191 hp & 216 ft/lbs tq

- 100% Stock Civic Si + Stage 1 Intake + Catted DP/FP Combo: 207 hp & 221 ft/lbs tq

- 100% Stock Civic Si + Stage 1 Intake + Catted DP/FP Combo + FMIC Kit: 216 hp & 224 ft/lbs tq

In other words we gained 9 hp and 3 ft/lbs tq by simply bolting on our FMIC kit in comparison to the factory intercooler setup.

Before anyone says it, we already know somebody is going to say, "OMG that's it?" Let's take a bigger look at this.

Here are three back-to-back (all runs within 2 minutes of each other) 4th gear dyno pulls with the stock intercooler, our Stage 1 Intake and catted downpipe/front pipe combo. As stated in an earlier thread, this car HATES 4th Gear dyno pulls from the factory. Notice the power loss from heatsoak during these back-to-back dyno pulls. This heatsoak only gets worse on hotter days or during even more extreme conditions like extended spirited driving and racing.

Run 6:

- Knock Value 55%

- Coolant Temp: 178 F Start / 189 F End

- IAT Pre IC: 99 F Start / 100 F End

- IAT Post IC: 99 F Start / 124 F End

Run 7:

- Knock Value 55%

- Coolant Temp: 190 F Start / 212 F End

- IAT Pre IC: 102 F Start / 102 F End

- IAT Post IC: 115 F Start / 138 F End

Run 8:

- Knock Value 55%

- Coolant Temp: 200 F Start / 228 F End

- IAT Pre IC: 107 F Start / 108 F End

- IAT Post IC: 126 F Start / 156 F End

Here are three back-to-back (all runs within 2 minutes of each other) 4th gear pulls of the same car, but with our FMIC kit added. The car responded MUCH better to repeated abuse and testing; heatsoak was drastically reduced.

Run 6:

- Knock Value 55%

- Coolant Temp: 181 F Start / 201 F End

- IAT Pre IC: 96 F Start / 96 F End

- IAT Post IC: 90 F Start / 99 F End

Run 7:

- Knock Value 55%

- Coolant Temp: 196 F Start / 217 F End

- IAT Pre IC: 100 F Start / 102 F End

- IAT Post IC: 95 F Start / 104 F End

Run 8:

- Knock Value 55%

- Coolant Temp: 199 F Start / 218 F End

- IAT Pre IC: 105 F Start / 99 F End

- IAT Post IC: 96 F Start / 106 F End

All dyno testing was performed on the same day. We saw as much as a 50 degree drop or an average of 36 degrees in post intercooler intake air temps on stock ECU mapping by simply swapping out intercooler setups. These results will only be amplified when running more boost via ECU tuning. More boost out of a tiny turbocharger = higher temps. Higher temps = increased chances of knock/detonation, thus limiting power and reliability.

Though the power gains may seem minimal on a stock or near stock car running factory boost levels, gains become much greater when turning the boost up and pushing things to the max. Aftermarket intercoolers are intended to reduce post intercooler intake air temps as much as possible to make the engine and forced induction system as efficient as possible, thus drastically improving engine/component longevity. We expect our Cobra CAI system to compliment this FMIC quite well in an effort to reduce intake air temps even more!

Update!

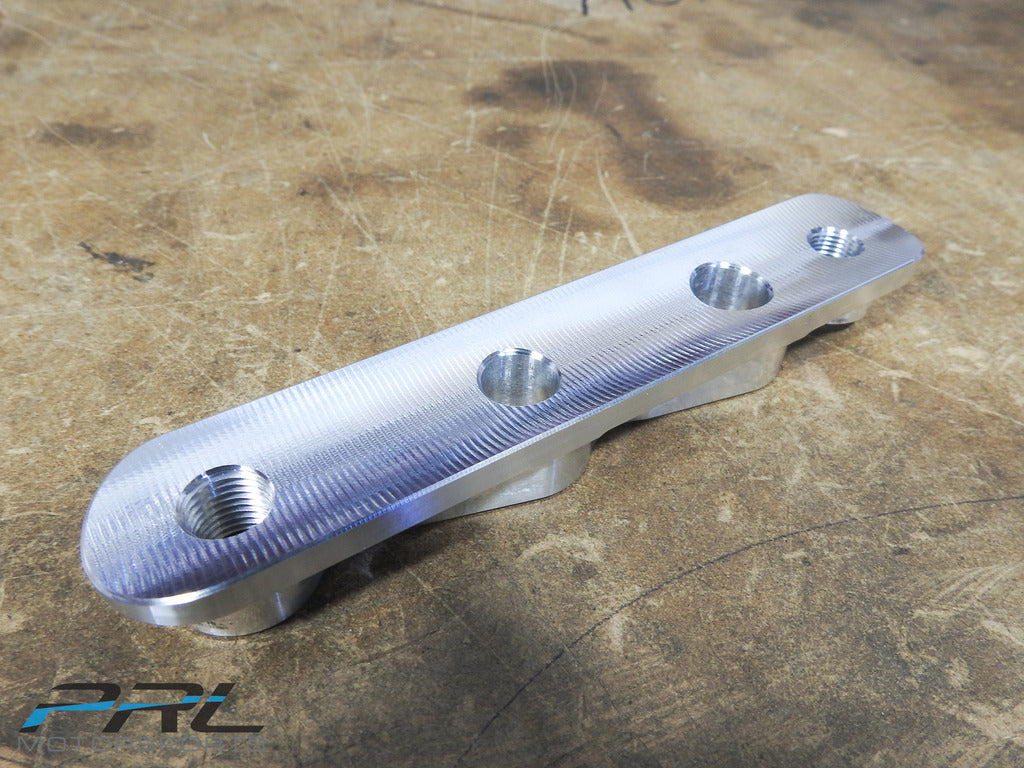

Aluminum bends for charge piping is here awaiting final fitment and welding with our billet aluminum flange/bung. This flange/bung also adds a 1/8" NPT threaded hole for misc uses. Once welded and bead-rolled the piping will head out to receive a textured wrinkle black powdercoat. 4-ply silicone couplers are entering final production and will be fastened with 304 SS Breeze liner clamps.

All intercooler cores are on a pallet ready to be welded and are just awaiting their cast end tanks. Our steel end tank molds were just finished and are awaiting a final quality/fitment check before starting production. Everything looks to be right on schedule so far!

Ask and you shall receive!

We've got two prototype intercoolers that we have used to check casting quality and fitment for production. The intercooler assembly fitment has passed with flying colors, so final production has begun.

...However, we did run into one little speed bump

One of our mandrel bends for the intercooler piping were slightly off, causing tight (too close for comfort) fitment. This isn't the end of the world, though, as we will have the bends fixed so we can weld and send to powdercoating!

We will have news for an ETA hopefully next week!

In the meantime, one of our prototype intercooler kits is heading over to @VitViper for testing!