Months ago, we, PRL Motorsports, set a goal to be the first 10th Gen Civic into the 10's on stock ECU a by any means possible; this is exactly what we accomplished. Full details of our build can be found in our Project Snow White Build Thread, but a quick recap on our build is as follows:

2017 Civic Si

- Stock ECU, currently on Hondata

- VP MS100 Unleaded Race Gas

- Zex wet shot nitrous kit jetted for a 100 shot w/ supplementary fuel system using Ignite e90

- Built engine w/ CNC Werx CSS cylinder block, Brian Crower connecting rods, JE 73.5mm 10.3:1 compression pistons & Brian Crower valvetrain, stock camshafts, stock valves and stock port head

- Stock transmission

- Clutch Masters 725 Race twin disc clutch

- PRL Motorsports Big Turbo Kit w/ GTX2860R GEN2, .86 A/R turbine housing (keep in mind this is the smallest turbocharger available with our kit) w/ catless downpipe

- PRL Motorsports 3” exhaust dump

- PRL Motorsports Cobra CAI w/ Race MAF housing

- PRL Motorsports FMIC w/ upgraded charge pipe kit

- PRL Motorsports front pipe

- Stock struts w/ D2 lowering springs

- Fast Brakes single rotor front brake kit

- Belak 13x9 front wheels w/ 8.7/25x13 M&H slicks up front and Belak 15x4.5 skinnies w/ 4.5/25x15 Mickey Thompsons

- Removed passenger seat, rear seats air conditioning and sunroof w/ Aerospec carbon fiber filler

Over the past few months we’ve learned quite a few things about these cars and the way the ECU makes them behave. Roughly 6 weeks ago we managed to put down 403 horsepower and 420 ft/lbs tq at 32 PSI on this same setup minus nitrous/supplementary fuel system and with the small .64 A/R turbine housing. Thinking that the turbine housing may have been a restriction, we decided to swap housings to rule this theory out. To our surprise, we did not see any notable gains at these boost/power levels. The power curve shifted to the right as expected, and did appear as if the car larger turbine housing would allow this engine to breathe at the top of the power curve with more boost/power. Knowing that the compressor map of the GEN2 GTX2860R is efficient to around 42 PSI, we planned to increase boost as much as possible, but needed a way around the factory MAP sensor limit, which would throw a CEL for over-boost at 30 PSI with the sensor’s maximum threshold measuring 32 PSI. Once we realized the 9th Gen Civic’s MAP sensor was a direct fit, KTuner enabled a fix to allow Hondata’s 4 Bar MAP sensor to be used in our car for testing. However, we faced new obstacles.

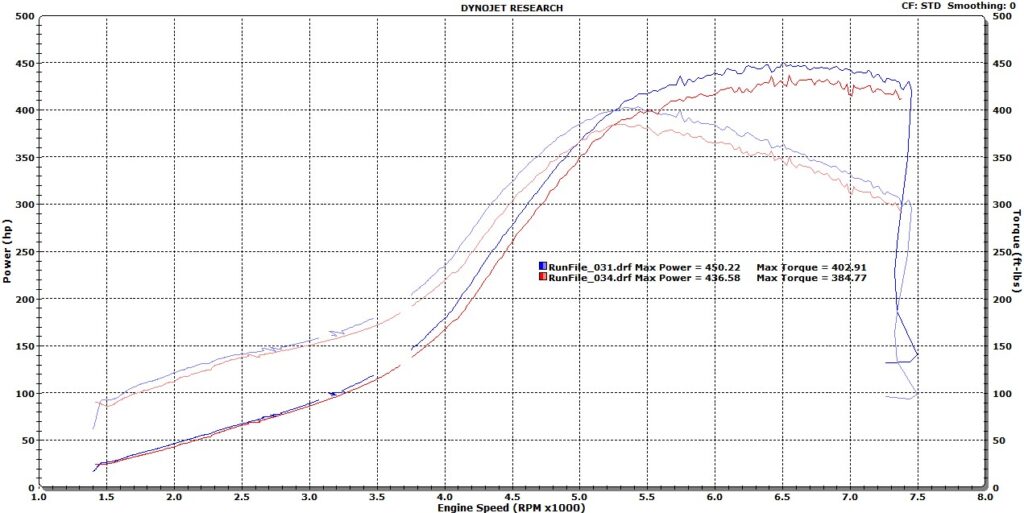

For reference, here was our previous 32 PSI KTuner map with and without a 100 shot of nitrous

Though MS100 allowed us to stretch the factory fuel system further than anyone has pushed things, we were still running out of fuel around 33 PSI, which prohibited us from achieving our goals without some sort of additional fueling. We have all the CAD drawings and means to offer the port injection kit we posted about months ago LINK HERE, the fact of the matter is this solution just isn’t quite feasible for the average consumer. The factory ECU currently doesn’t have the means to control this, and the available controllers are not exactly designed to work properly with this DI platform. Even once figured out if possible, the cost and efforts of an additional fuel cell/surge tank, fuel pump, injectors, injector spacer plate w/ fuel rail, fuel lines w/ fittings, 1:1 fuel pressure regulator, injector controller, etc. far outweigh the cost and efforts of a nitrous kit.

We tested various different shots of nitrous along the way, from 55, 65, 75 and 100 shots. Boost pressure rises 2-4 psi depending on the shot of nitrous, which also aids in power output. The factory plastic-composite intake manifold has been known to split/leak around 40 PSI for various but expected reasons; the 9th Gen Civic Si faced similar problems with its factory composite intake manifold as well. For this reason, slightly lower base boost pressures with a minor rise in boost from nitrous allows our car to keep the factory intake manifold together.

Our car managed to run 11.23 at 127 mph and 11.23 at 128 mph with a 65 shot. The following week our car managed to run two 11.02 passes at 131 mph, one on a 75 shot and the other on a 100 shot. During all of these runs at the track, we began to notice a major underlying problem which prohibited us from running faster times. Why would the car run similar times on a 75 shot and 100 shot with a similar short tracks?

Back when we began cresting 30+ PSI, we noticed intermittent ignition timing oscillation that only seemed to be noticeable on the street/track. As we began pushing things further, this oscillation became more prominent. The first 11.0 pass was with a near-perfect log on the 75 shot. The next 11.0 pass with the 100 shot showed us that there was as much as a 15 degree fluctuation in ignition timing during the run. Looking back on most of our low 11 second logs, we had major fluctuations in timing, which greatly hindered power output and quarter mile times.

Until this point, our car utilized a manual boost controller like the rest of our turbo kits. Hondata’s initial turbo kit basemap that was released a few weeks ago was configured for a pneumatic wastegate actuator as well. Our previous testing with this basemap showed that our setup was seeing the same issues with both tuning platforms. However, we’ve been working on another project that’s been under wraps for quite some time; utilizing the factory electronic wastegate actuator with our turbo system. Given the struggles that we’ve faced and readiness to test our first prototype, Hondata offered their assistance to bring both our prototype and goals to life. A few days later, Hondata was on their way to PRL to see what we could accomplish.

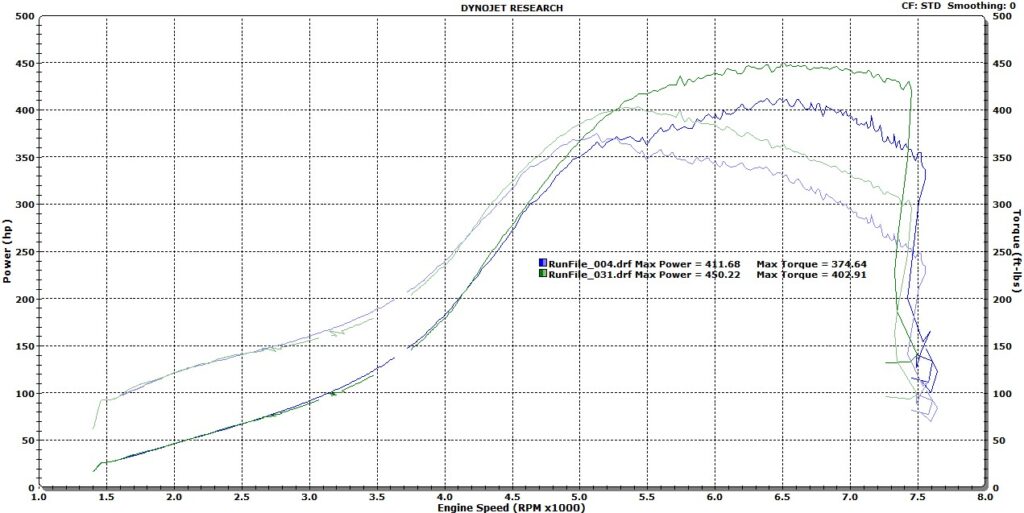

Here is our first Hondata tune at 32 PSI with pneumatic wastegate actuator and unfinished cam timing vs finalized Hondata tune at 32 PSI and electronic wastegate actuator with finished cam timing.

Upon startup on the Hondata PRL Motorsports Big Turbo Kit basemap, the initial map left much to be desired, but that’s purely what it was; a basemap. The first two days of the three day visit set the tone for how the rest of this week would pan out. Hard work and dedication from all parties at hands figured out quite a few notable things here: First and foremost, the fact that the factory electronic wastegate actuator can now be utilized was huge! Various background coding has been figured out to allow smoother power delivery up top, and also eliminated a massive power drop after ~7000 RPM. We are now up almost 80 horsepower where we were previously diving on the Hondata basemap. All of this allowed us add more timing without increasing knock control to achieve our final numbers of achieve 617.62 horsepower and 520.53 ft/lbs torque in comparison to our previous best of 532.76 horsepower and 476.14 ft/lbs torque. These were huge gains! On day three, the oscillation issues we were experiencing seemed to have been figured out. The only thing left to do was take our car to the track and test our dyno data.

Here’s are two 32 PSI Hondata runs, with a 3 degree difference in timing.

Here are two 32 PSI Hondata runs, with a 6 degree difference in timing.

We managed to run four times the past Friday 6/7/19, all of which showed great promise. The first three runs were great passes straight off the trailer. Best of all, there was little to no timing fluctuation. Run 4 of the night brought us to 10.99 at 133.57 mph, the first 10th Gen Civic into the 10’s and we’re just scratching the surface! This setup still has so much left in it, especially after the available software is refined.

Stock Civic vs 32 PSI GTX2860R GEN2 VS 32 PSI GTX2860R GEN2 w/ 100 shot of nitrous

By itself

This never was and never will be a KTuner vs Hondata debate for us, even though the some of the community has and will continue to spin it that way. We’ve had a MoTeC M1 plug ‘n play standalone unit sitting on our shelf for months that we have plans to utilize once we feel that we have maxed out the factory ECU’s full potential/capabilities. Our goal was to show that the community doesn’t need a $5,000+ standalone ECU to run 10’s and/or make impressive power. We understand that MoTeC (or the necessary supporting mods) isn’t for everyone, so we’ve continuously worked with two excellent companies to push the factory ECU and basic flash software to a point that can suit most anyone’s power goals. PRL Motorsports is a performance parts manufacturer whose goal is to be compatible with every tuning platform on the market for universality’s sake; it only makes sense. We never have and never will work exclusively with any company, as we feel that this only hinders market reach and the potential to push the platform further for the end user.

Everyone can/will take away what they want from this, but they can't take away the countless hours and money spent on turbo kit R&D, dyno time, tuning, car-prep, and track time from so many individuals after business hours and on weekends. We do this because we love it and want to offer the best performing product(s) that have been repeatedly backed up. No discredit to anyone involved along the way, especially KTuner and Hondata. In the end, this will only push all three companies to continue to develop and offer new, innovative technology and products which ultimately benefits the community as a whole.

Keep in mind that all of this has been done on the same engine (installed in February), transmission, axles, etc. Never once has anything been broken. Our car has 20-25 hits at the track on nitrous, 30-40 hits on the dyno nitrous and many, many more off the bottle. We didn’t want to initially shock the public with the fact that we were running nitrous due to the major misconception that “you’ll blow the welds on your intake manifold, bro.” We always want to keep the public as educated as possible and make sure our products perform as intended.