The Evolution

Since Honda’s release of the FK8 Civic Type-R in 2017, the community’s expectations and power goals have gradually evolved. For some, a 300-horsepower platform out of the box was enough to have fun – for others, a full bolt-on package netting mid to upper 300’s was plenty. As time went on, though, customers began to realize that they were just a fuel system upgrade away from making more power. And if you were already planning on purchasing a fuel system upgrade, why not purchase some sort of turbocharger or system upgrade? Do you purchase a drop-in turbocharger upgrade, or do you want to look into a full big turbo kit? Just how deep are you willing to go, and at what point are there diminishing returns? Welcome to the wonderful world and addiction of vehicle modification.

As a company rich in racing heritage, we’ve always understood the importance of retaining optimal spool and powerband, especially for track-intended vehicles such as the FK8. We’ve also understood the many limiting factors of Honda’s modern platforms, which tend to be quite pricey when looking to achieve big power goals. For these reasons, we felt that a drop-in turbocharger upgrade only makes sense when looking to appeal to the masses, at least for this platform. But, this isn’t to say that drop-in turbochargers don’t have their drawbacks.

When designing a drop-in turbocharger upgrade, we as manufacturers have to keep in mind the spacing constraints when fitting larger components (such as wheels, shaft and bearings) into the factory frame footprint. From its release and until now, our P600 turbocharger was the largest drop-in turbocharger option on the market for the 2.0L Turbo Honda / Acura platform(s). The P600 has proven to offer the most ideal powerband for customers looking to efficiently make upwards of 600 horsepower. However, as these platforms continue to evolve, it's apparent this number still isn’t enough for customers looking to push their cars even further. So how can we increase power potential?

If There's a Will, There's a Way

Our team has analyzed all of the data that we’ve collected since the start of our P600 development in 2019 and put together a list of common limitations or required adjustments if looking to make more power. Two key factors were prevalent – excessive shaft speeds and backpressure. For us, this was no real surprise, as the A/R of the factory turbine housing was not reworked. We chose not to do so in an effort to retain turbocharger spool. Signs of high backpressure are apparent on any factory frame turbocharger at higher boost levels (dependent on vehicle/setup).

Most people are familiar with turbocharger boost pressure (typically measured in PSI), but rarely do folks discuss turbocharger shaft speed (measured in RPM). In the past, turbo speed wasn't monitored by most, as it wasn't a common cause of issues with larger frame turbochargers. Now that smaller frame turbos are becoming more popular, turbo failures due to high shaft speeds are becoming more common.

Generally, the pressure ratio increases as shaft speed increases. However, every turbocharger / compressor will have a choke point, which is associated with maximum shaft speed. As the turbocharger reaches or surpasses this choke point, compressor efficiency begins to drop drastically and turbocharger shaft speed will also be nearing or exceeding its acceptable operating limit. The chances of turbocharger overspeed are very high when operating near the choke point.

Typically, the remedy for compressor choke point is to upgrade a larger compressor wheel. Unfortunately, though, it is not that simple. Manufacturers face major spacing constraints when trying to fit large turbine and compressor wheels into factory location turbocharger upgrades. There is also a desired inducer to compressor ratio for optimal balancing and performance that we have to keep in mind. However, there are other tricks that turbocharger manufacturers can do to increase compressor efficiency, such as anti-surge compressor housings or ported compressor shroud covers. These tricks can help increase airflow by up to 30% (depending on turbocharger and application) and reduce compressor surging.

High exhaust back-pressure is another common issue with factory location turbocharger upgrades. Due to spacing constraints, there often isn't enough room in the engine bay or surrounding areas to increase the size of the turbine or compressor housing(s). Generally, as boost pressure is increased, so is exhaust back pressure. Back pressure can be relieved through a larger turbine wheel or housing. Doing so, however, will hinder turbocharger spool/response and require the room to do so. We at PRL prefer to offer the largest turbine wheel possible to fit a given housing frame to offer the greatest exhaust/power flow and response while remaining a direct-fit turbocharger. It is also important to note the vehicles at higher elevations require the wastegate to be shut more than vehicles at lower elevations to make the same boost and/or power level, ultimately increasing backpressure at the same power output.

*Disclaimer*

It is important to note that just because a turbocharger or wear-and-tear component is capable of producing a maximum of X horsepower, it usually doesn’t mean that customers should expect maximum longevity or reliability out of said product or component. For example, customers running a 500 ft/lb torque rated clutch kit should not expect optimal life or longevity at power levels approaching this rated limitation. Boost pressure, dyno numbers and general power output numbers are all subject to vary depending on numerous variables, such as fuel quality, supporting mods/components, engine health, engine compression rating, rev-limit, elevation, ambient temperature, humidity, dyno, ECU calibration, tuner, etc.

TLDR

In short, there is no possible way to safely or efficiently make more power without reducing shaft speed or backpressure. After examining the P600 design, we were able to fit an even larger, high-efficiency compressor wheel (58mm Inducer / 71mm Exducer) in effort to reduce turbocharger shaft speeds while also offering increased airflow. We were also able to increase the wastegate bore from 31mm to 34mm to reduce backpressure and improve boost control. A larger wastegate bore will increase the area of exhaust for exhaust gasses, which alleviates back pressure. These modifications increased performance drastically, without hindering turbocharger response.

And yes, it will fit your 2.0T Accord, TLX & RDX!

With all of the growing interest in the 2.0T platforms outside of the FK8 Civic Type-R, we've integrated a primary o2 sensor bung that is cast into the turbine housing for direct fitment/compatibility of the 2018-2023 Honda Accord 2.0L Turbo, 2021+ Acura TLX 2.0L Turbo and 2019+ Acura RDX 2.0L Turbo.

Testing the P700 Turbocharger

Given their reputation for pushing the limits with the FK8 platform, we figured Red Star Motoring would be the perfect candidate for testing out our new turbocharger. Pepo installed our P700 turbocharger on his shop vehicle and was able to make put down 583 hp and 477 ft/lbs of torque at 34 PSI while also reducing backpressure ~10 PSI at the same power level in comparison to the P600. We then asked Pepo to put some street and track miles on it for further testing.

Though it's not exactly an apples-to-apples comparison, it's worth noting that we were previously only able to see a best of 575 hp and 487 ft/lbs of torque during Pepo's original P600 testing at 36 PSI.

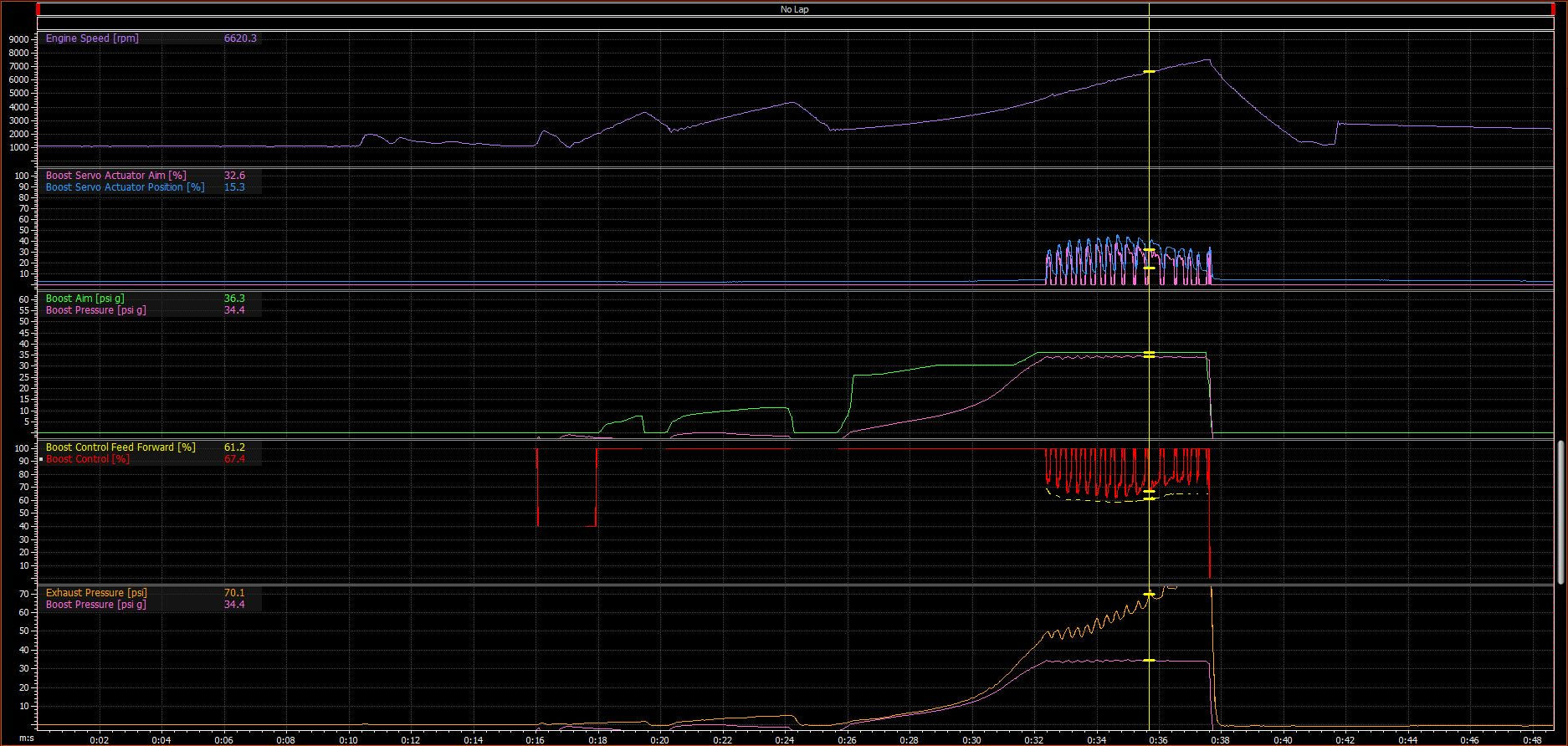

Taylor King at Perform NC offered to test another prototype turbocharger in his search for a wider power band than his previous G35-1050 big turbo kit setup. Taylor was able to use his extensive build list and MoTeC ECU to help us collect some great data while pushing this turbo’s limits. Taylor installed an EMAP sensor to log backpressure so we could accurately see what's going on. The plan was to log turbocharger response and gradually increase boost, starting at 28 PSI, to monitor backpressure and power output.

We were able to see full spool by 3950 RPM - it’s worth noting that this is with a large, race-style intercooler, ported cylinder head and camshafts. Taylor was able to produce 571 horsepower and 430 ft/lbs of torque at 28 PSI, with the wastegate open and back pressure staying at/below 2:1.

At 30.5 PSI we saw 600 horsepower and 482 ft/lbs of torque, without wastegate closure or backpressure issues.

At 34 PSI, the wastegate remains about 47% open, with back pressure staying at/below 2:1 until about 6775 RPM. For reference, most stock frame turbochargers would experiencing high back pressure due to wastegate closure well before this point.

As the engine continues to rev past ~6700 RPM, we can see backpressure begin to quickly surpass the desired 2:1 backpressure target, meaning that turbine becomes a restriction past this point.

At 35 PSI, we were able to see the wastegate position begin to close around 6000 RPM, with backpressure staying at/under 2:1 until around 6600 RPM. Taylor was able to make a best of 640 horsepower and 501 ft/lbs of torque at this boost level. Both parties agreed that 35 PSI was a "comfortable" stopping point when considering all of the factors coming into play here.

Looking at the above dyno graphs, we can see a smooth power curve at 28 PSI when back pressure is at/below 2:1, which coincides with Taylor's datalogs. We can also see that the power curve begins to change its rate of increase when backpressure surpasses 2:1.

What About Shaft Speed??

When comparing P600 and P700 compressor maps, we can estimate a 165,000 RPM shaft speed at 600hp on a P600 turbocharger vs roughly 140,000 RPM at 600 horsepower on the P700, or a difference of 25,000 (15%). At 500 horsepower, we can estimate a shaft speed reduction of 30,000 RPM for the average consumer.

Conclusion

Our P700 turbocharger effectively reduces backpressure and slows down shaft speeds. These upgrades provide an even more efficient and powerful turbocharger at all boost levels, whether looking to make big power or moderate power at low(er) boost levels. Because we of all of these advantages and unsacrificed spool time, we will be superseding the P600 turbocharger with the P700 from this point forward. Pricing will remain the same at $2649.99. Pre-orders and inventory are expected to be released within the next few weeks. Stay tuned!

Comments (22)

Hello!!! I recently bought a 2021 Acura TLX. 4cyl Turbo. Now wanting the V6. If I were to purchase this latest P700 would I need many other parts to handle the extra power. Or am I starting a whole new Hotrod project. I’m looking for more power but not another endless project. Thank you. Chris

Are there any parts required outside the P700 that I need to install in my 2024 type S Integra and will I notice an increase in horsepower once switching the turbos out?

How many HP will my car gain with the P700 alone everything else OEM stock? I have a 2021 Acura TLX 2.0 A-Spec SH-AWD. Thanks

Chris

Can you send me the complete list of mods for 2020 Honda Accord 2.0T sport ?

What are all the parts and tunes that I need to install this on my stock 2018 Honda Accord Sport 2.0t?

Why does the p700 has issues building boost anything over 20 psi it would not go over 20 psi, electronic wastage was checked and pressure tested/smoke tested intake system, no leaks found, the tables are not the issue either car should be making high amount of boost but it would not go over 20 psi,( I had a type r oem turbo before making 23psi)

I have a 2021 honda accord 2.0t, I have everything bolt-on besides the E85 Tune and the P700, I’m currently running everything off of KTUNER and with stage 3, will there be a tune for or KTUNER’s to help tune everything correctly?

I have a 2021 honda accord 2.0t, I have everything bolt-on besides the E85 Tune and the P700, I’m currently running everything off of KTUNER and with stage 3, will there be a tune for or KTUNER’s to help tune everything correctly?

What mods will be necessary before installing the p700 turbocharger on my ‘22 Accord 2.0T Sport? My current mods are PRL V1 Cold Air Intake, PRL Intercooler w/ charging pipes, ported throttle body, and FlashPro tuned.

I have a mishimoto intercooler, catted PRL downpipe, magnaflow exhaust and mishimoto intake box. I do also have a Ktuner V2. Will additional upgrades be necessary to run this turbo? I am not going to be looking to push max horsepower, but would like something powerful yet as reliable as the stock. Would this make sense? Do I need to upgrade the turbo inlet?