Source :https://www.facebook.com/innovativemotorworks/posts/2073066539388019

Every few days, a thread pops up on social media groups regarding intake selection on the popular 1.5T Honda Civic model range. This is often the begining of a 300-comment-deep stream of users sharing responses like "Brand X works just fine on my car," or "Brand Y sounds the best."

From a tuning aspect, what makes an intake the "best?" The one that makes the most power is the obvious first answer, as we're all seemingly in pursuit of the most "bang for the buck." One thing that's often overlooked is the quality of the signal to the Mass Airflow meter (MAF, AFM, etc). For the last decade, Honda has moved largely away from entirely speed density fueling in favor of airflow metering. No longer can you shove a filter on a generic tube of any size/length and the ECU be happy.

Over the last few months, some names have been debated greatly in terms of intake design for this platform. The following manufacturers were contacted for this test: Injen, PRL Motorsports, 27Won, K&N. After waiting two months for everyone to step up to the plate, only PRL and Injen were available for testing. That being said, PRL versus Injen is essentially the biggest divide in the community at this time, so it worked out.

So let's start with some information about the test. All tests were performed on a 2017 Civic Si with 5,500 miles on the clock. The only modifications on the car are a ClutchMasters FX400 clutch, a FlexFuel sensor (disabled for testing), and a PRL "Stage 1" filter/silicone hose (which was worth 3hp repeatably in previous testing over the stock intake arm/filter). The fuel type used was 93 octane gasoline that contains 10% ethanol. To represent the average consumer, an off-the-shelf KTuner "23psi" starter map was loaded to the ECU. The tests were done back-to-back, with the car never being unbolted from the dyno. Three runs were performed with each intake. The first two runs on each intake were back to back, with the third occurring after a brief rest at idle, with the hood closed to simulate performance from a heatsoaked stoplight situation. ECT's on all runs started at 177degF, and IAT2's on the first starting tests were 82deg. IAT1's varied due to intake design. Boost pressures were consistent across all tests, along with AFR target at WOT (11.1:1).

The testing went in the following order:

1) PRL "Stage 1"

2) Injen

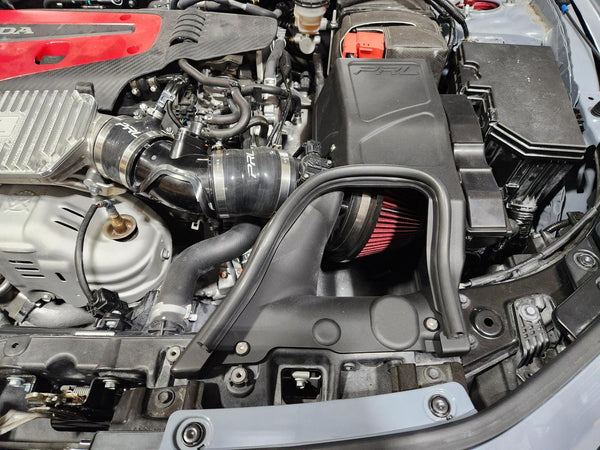

3) PRL "Cobra" (Street MAF)

The testing showed a larger peak torque gain with the Injen right after spool-up (5lb-ft), but when it came to total power production and top end gains, the PRL comes out on top. There was a 13hp gain over the PRL Stage 1 at 6,400rpm. You can see how heatsoaked affected each intake, as represented by the blue line run on each set (the hood closed run after some idle time).

The biggest difference between the intakes was the quality of the MAF signal. The Injen intake's unorthodox MAF housing design (pictured) resulted in the ECU needing to pull 15-16% fuel at WOT in places to achieve the targeted air-fuel ratio. Luckily, the 10thGen Civic operates in closed loop at wide open throttle most of the time, but a 16% fuel adjustment is enough to make the car run deep into the 9's AFR without the correction. During part throttle operation, -20% short term trims were seen consistently. The PRL Cobra's "Street MAF" on the other hand was within 2-3% throughout the pulls with the stock MAF curve, and within +/-5-6% during partial throttle. The corrections with the PRL Cobra were consistent with the OEM MAF housing, which is a great feat. What does this mean? If you buy an Injen intake, you're going to need recalibration of the MAF scaling for proper operation.

The verdict? Besides the obvious gains (and consistency seen between the runs), the PRL "Cobra" is by far the better engineered and constructed unit, as evidenced by the quality of the airflow meter signal and limited short term adjustment necessary by the ECU. It should be noted that the Injen's MAF inlet was poorly handled during manufacturing, also. As seen in the photos, it appears as if someone took a metal die grinder to the hole after welding in order to clean it up, and damaged the edges, which were then just powdercoated over. This left a sharp edge around the area in which the rubber o-ring on the MAF is meant to seal.