Pulled from 9thgencivic Forum

https://www.9thgencivic.com/forum/build-section/175314-prl-motorsports-motor-build-thread.html

*note we no longer offer engine building services*

We decided to put together some official motor packages for the 9th Gen Civics. We received quite a few calls and emails about our packages lately and got our hands on a complete motor to document a build thread for the community. This customer decided to go with our PRL Motorsports Stage 2 short block which is made up of our Darton MID sleeves, Wiseco pistons with upgraded wrist pins, Manley Turbo Tuff rods, tri-metal race bearings and ARP studs tying together our soon to be listed R40 head package!

Stay tuned for updates!

Denis ccing a K24Z7 head so the 9th Gen community can have an accurate reading on the single port R40 heads! Our readings indicated that these cylinder heads are 54cc, which means we can now guide customers in the right direction with their motor builds and part purchases.

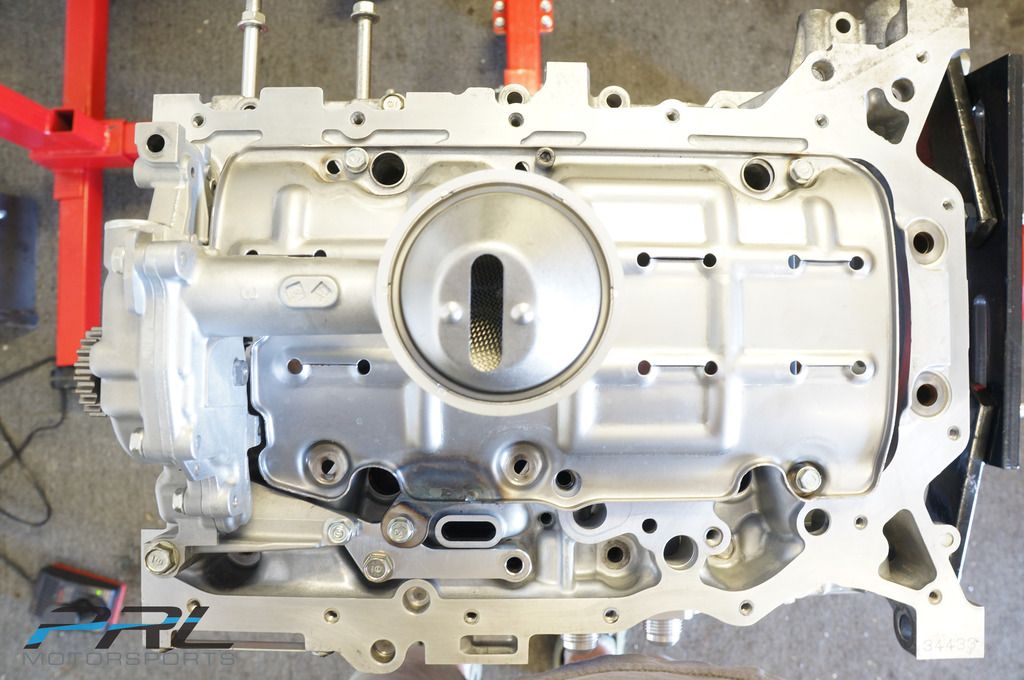

When building these K24Z7 motors to turn out big power and 8000+ rpms the factory oiling system becomes inefficient and problematic due to the balance shafts the OEM oil pump uses. The most common and cost-effective solution to this is swapping in the Acura RSX Type-S PRB oil pump to eliminate the balance shafts and better supply oil. However, there is no real way to install the PRB oil pump and windage tray properly without rigging everything up... until now.

We decided to introduce our new PRB / Type-S Oil Pump Swap Kit which is the first and only "bolt-on" PRB oil pump swap for the K24Z motors! Our Kit will include a modified PRB oil pump with all (3) bolts needed to properly install, the oil pump chain, chain guide, tensioner, and (3) bolts needed to properly install as well. The kit also includes the windage tray, (5) bolts, a spacer, (2) NPT pipe plugs, our PRL Motorsports Oil pump mount with bolts, and PRL Motorsports oil filter block-off plate. Customers will need to modify their girdle to use our kit properly, or can send their girdle in to us to be machined, drilled and tapped for an additional price.

Darton MID sleeves

Factory sleeves getting ready to come out

What the block looks like after CNCing the factory sleeves out

Can't forget the ARP main studs for added safety!

What our torque plate (also available on our website) looks like torqueing everything down to simulate the load and distortions this K24Z7 will see during use

Freshly pressed in Darton sleeves

Each of our block surfaces receive this finish, and our Stage 2 sleeved blocks receive a groove around the tops of the sleeves for a copper O-ring to ensure an even better seal!

Later this week we will do hone the cylinders for their final spec and finish so we can finish the short block assembly!

Our stage 2 short blocks all receive pistons with upgraded wrist pins for added safety. Typically we like to see the wrist pins upgraded on motors making 650 + hp, so it only makes sense to include these as a standard for guys looking to make power! Here is a comparison

We used the cylinder head CC data that we figured out early to calculate which pistons would give us our desired compression. Flat top pistons will give us around 11.0:1 compression with the slight resurfacing of the block and head surfaces. With compression being 11.0:1 from the factory and seeing how well these cars respond, we recommend sticking around this number, especially given the fact that the sleeves have now been upgraded, rods and pistons are forged and both customers will most-likely be using e85 which burns cooler. This compression ratio will keep quick turbo response and respond better to boost when turning it up. On the left we have a piston (which our customer later ended up moving to a flat top) that is typically the standard "turbo piston," which would give us about 9.8:1 compression in this application. On the right we have a flat top.

Our stage 2 blocks also receive Manley Turbo Tuff I-beam rods which we use in all of our builds making 600 hp to about 1000 hp!

Here is one of the heads we put together for these builds. Supertech valves, 85 lb dual valve springs with Ti retainers, Supertech keepers, spring seats bronze valve guides and valve seals. Now we can safely rev the motor out and deal with the heat and abuse of anti-lag and high horsepower racing!

Jay finished the short block assembly for one of these Stage 2 short blocks, complete with our PRB Type-S oil pump swap kit!