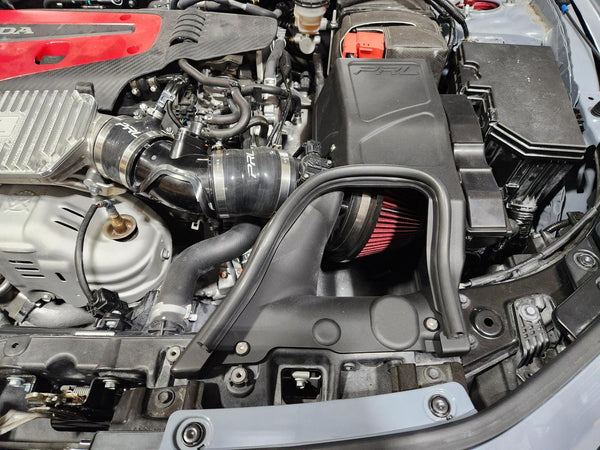

Project Snow White 10th Gen Si is now underway! We will be using this White Orchid Pearl coupe to test our PRL Motorsports products and push the limits of Honda's new DI 1.5T platform with the help from KTuner, LLC. First mod? Our Stage 1 Intake system while the dyno is getting moved this week.

Like our past record setting 9th Gen Civic shop car, we will provide baseline dyno numbers and data with our in-house Dynojet Research Inc. We will also be testing and backing up our Civic X product line with before/after gains on the dyno and at our local Keystone Raceway Park drag strip and Pitt Race road course.

Our first impression? The 10th Gen Si is a very comfortable and well-performing car on the street; much more fun to drive than the 9th Gen Civic Si stock-for-stock. We are confident that this 1.5T will churn out some very fun/impressive power with a reflash and simple bolt-ons. One major complain is how weak and spongy the factory clutch feels. The excessive rev-hang isn't too fun either, but this shouldn't be a problem for long

So far we have confirmed that the following products currently fit both Si and Non-Si Civics:

- Downpipe/Front Pipe Combo

- Downpipe

- Front Pipe

- Stage 1 Intake System

- Stock Replacement Intake Hose

- High Flow Drop-In Air Filter

We are currently in the final stages of developing/testing our Cold Air Cobra Intake system for both the Si and Non-Si platform as well as our FMIC kit, stay tuned!

An upgraded 6-puck clutch is on its way to us from Clutch Masters as of today, and we are working on narrowing down a proper wheel/tire choice to handle road course abuse. Slicks, skinnies and proper suspension are next on the list to be ordered.

We got around to dynoing our Project Snow White Si earlier this morning and put together some graphs/data for the forum. We began testing this morning with the stock intake when the temperature was in the upper 60's (Fahrenheit) which is rather mild for this time of year in PA. Immediately we noticed how sensitive and vulnerable these cars are to heatsoak.

Above are three consecutive dyno pulls with only a few short minutes between each, notice how drastically power is lost as heat accumulates. The car made a best of 187 hp and 215 ft/lbs tq during the first pull. Typically we like to start dyno pulls around 180 degrees Fahrenheit for coolant temps and 100 degrees for air temps. We saw a max of 225 degrees for coolant temps and around 115 degrees for air temps towards the end of run 3. Notice how power drops at around 4400 RPM for runs 2 and 3? The knock control value increases and the ECU pulls timing.

Here is a comparison of heaksoaked 3rd gear pulls and heatsoaked 4th gear pulls. Notice a trend?

The car liked 3rd gear pulls much better, it kept temps almost tolerable. We saw 196 whp and 205 ft/lbs tq here.

While we were at it we decided to do some before/after runs testing our Stage 1 intake system. We never really anticipated this kit to be a big power maker, more or less a simple bolt-on mod for customers looking to improve aesthetics and air flow. With that being said, we were rather impressed with what we came to find during testing.

We recorded four dyno pulls with the Stage 1 Intake system. During the four 3rd gear pulls we noticed that the knock control value continued to drop, which shows an increase in efficiency, whereas the knock control value with the factory intake system is rather sporadic. As this knock control value decreases the ECU continues to add timing and allow the car to make more power. Our stock 10th Gen Civic Si made a best of 200 whp and 210 ft/lbs tq on our DynoJet.

Here is a 3rd gear comparison of the stock intake system and our Stage 1 intake system. We chose to compare these runs because of how identical knock control values, coolant temps and air temps were (within +/-1%).

Here is a 4th gear comparison of the stock intake system and our Stage 1 intake system. Again, these two graphs show identical parameters. These numbers and gains held consistent into the late morning when temperatures rose about 7 degrees Fahrenheit into the mid 70's

With that being said, we managed to see measurable gains with our Stage 1 intake system in comparison to stock. Customers can expect a 4-9 whp gain without a tune by simply bolting in our high flow drop-in filter and silicone intake hose. We expect to see MUCH larger gains with our cold air intake system.

Keeping coolant and air temps cool is crucial to keeping your engine happy. We are going to experiment with a thicker, more efficient radiator to improve cooling, as well as begin testing our FMIC and CAI to see how that effects air temps!

FMIC Friday? Finally we have some dyno testing and data for you guys!

Here is an overall comparison from what we have gathered thus far with our 2017 Civic Si in terms of gains. We chose the dyno runs to compare because these are all 4th gear pulls with identical coolant temps and knock values (~55%). All of these pulls are untuned and using the factory Honda ECU mapping.

- 100% Stock Civic Si Baseline: 186 hp & 215 ft/lbs tq

- 100% Stock Civic Si + Stage 1 Intake: 191 hp & 216 ft/lbs tq

- 100% Stock Civic Si + Stage 1 Intake + Catted DP/FP Combo: 207 hp & 221 ft/lbs tq

- 100% Stock Civic Si + Stage 1 Intake + Catted DP/FP Combo + FMIC Kit: 216 hp & 224 ft/lbs tq

In other words we gained 9 hp and 3 ft/lbs tq by simply bolting on our FMIC kit in comparison to the factory intercooler setup.

Before anyone says it, we already know somebody is going to say, "OMG that's it?" Let's take a bigger look at this.

Here are three back-to-back (all runs within 2 minutes of each other) 4th gear dyno pulls with the stock intercooler, our Stage 1 Intake and catted downpipe/front pipe combo. As stated in an earlier thread, this car HATES 4th Gear dyno pulls from the factory. Notice the power loss from heatsoak during these back-to-back dyno pulls. This heatsoak only gets worse on hotter days or during even more extreme conditions like extended spirited driving and racing.

Run 6:

- Knock Value 55%

- Coolant Temp: 178 F Start / 189 F End

- IAT Pre IC: 99 F Start / 100 F End

- IAT Post IC: 99 F Start / 124 F End

Run 7:

- Knock Value 55%

- Coolant Temp: 190 F Start / 212 F End

- IAT Pre IC: 102 F Start / 102 F End

- IAT Post IC: 115 F Start / 138 F End

Run 8:

- Knock Value 55%

- Coolant Temp: 200 F Start / 228 F End

- IAT Pre IC: 107 F Start / 108 F End

- IAT Post IC: 126 F Start / 156 F End

Here are three back-to-back (all runs within 2 minutes of each other) 4th gear pulls of the same car, but with our FMIC kit added. The car responded MUCH better to repeated abuse and testing; heatsoak was drastically reduced.

Run 6:

- Knock Value 55%

- Coolant Temp: 181 F Start / 201 F End

- IAT Pre IC: 96 F Start / 96 F End

- IAT Post IC: 90 F Start / 99 F End

Run 7:

- Knock Value 55%

- Coolant Temp: 196 F Start / 217 F End

- IAT Pre IC: 100 F Start / 102 F End

- IAT Post IC: 95 F Start / 104 F End

Run 8:

- Knock Value 55%

- Coolant Temp: 199 F Start / 218 F End

- IAT Pre IC: 105 F Start / 99 F End

- IAT Post IC: 96 F Start / 106 F End

All dyno testing was performed on the same day. We saw as much as a 50 degree drop or an average of 36 degrees in post intercooler intake air temps on stock ECU mapping by simply swapping out intercooler setups. These results will only be amplified when running more boost via ECU tuning. More boost out of a tiny turbocharger = higher temps. Higher temps = increased chances of knock/detonation, thus limiting power and reliability.

Though the power gains may seem minimal on a stock or near stock car running factory boost levels, gains become much greater when turning the boost up and pushing things to the max. Aftermarket intercoolers are intended to reduce post intercooler intake air temps as much as possible to make the engine and forced induction system as efficient as possible, thus drastically improving engine/component longevity. We expect our Cobra CAI system to compliment this FMIC quite well in an effort to reduce intake air temps even more!