We understand that everyone has been eagerly awaiting a better intake for the FL5 Type-R. The development phase of our High Volume Intake is nearing completion, and the testing phase is about to begin. Before we dive into the changes and reasons behind them, let's first take a look at the factory intake.

As we can see, the factory rubber inlet snaps to the box and comes up and over the core support. This rubber duct seals to the hood and channels air into the airbox using a duct at the front of the car, in front of the radiator support.

Through our experience with the FK8, we've learned that keeping these cars cool during hard driving is essential for performance. In our Intercooler Test Data blog, we showed that the car was down 65hp from stock at full heat soak. With this in mind, we wanted to find a way to let the maximum amount of air into the box without blocking flow into the radiator with a large front scoop.

When we looked at the design of the factory airbox, we noticed that the inlet to the box was limited by the small rectangular opening where the duct interfaces with the box. The opening is limited due to the two-piece design of the factory box. So how did we increase the size? By using the same method we used on the FK8 - integrating the duct into the design of the airbox. This allows the opening of the box to be significantly larger, eliminating any restriction associated with airflow into the box.

Using this design philosophy, we were able to increase the minimum area of the opening for airflow by 133%.

In direct comparison, we can see that the opening into the PRL High Volume is significantly larger and less restrictive than the opening into the factory airbox. If the engine can breathe more freely, it will make more power.

To maintain the free-breathing design language throughout the entire intake system, we have also included our typical stepped silicone design, which port matches each piece of silicone to each connection point. This ensures a smooth transition between all intake components and minimizes intake tract resistance.

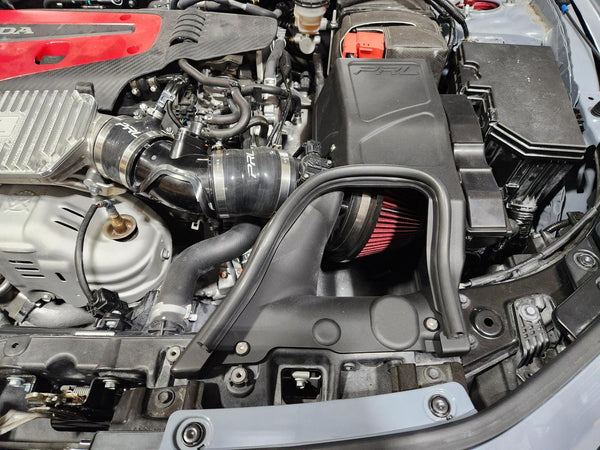

Some other exciting news, the airbox shown in the pictures is a fully functional 3D printed prototype. We’re very excited to get the prototype on our FL5 so that we can test the intake and report on the results. Stay tuned for more information on how all of our changes to the intake actually affect performance!

Comments (11)

Will there be a race maf option in the future like the fk8, or just a standard street maf housing like the 11th gen HVI?